Innovative Fasteners and Machining Solutions for Intricate Styles

Innovative Fasteners and Machining Solutions for Intricate Styles

Blog Article

Navigating the Globe of Fasteners and Machining: Techniques for Accuracy and Rate

In the elaborate world of bolts and machining, the mission for accuracy and rate is a perpetual difficulty that demands careful interest to information and critical preparation. From recognizing the varied selection of fastener types to picking optimum products that can withstand rigorous needs, each action in the procedure plays an essential function in accomplishing the preferred outcome.

Understanding Fastener Types

When choosing fasteners for a project, understanding the numerous kinds offered is vital for ensuring optimal performance and integrity. Bolts are available in a large range of kinds, each created for certain applications and demands. Bolts are made use of with nuts to hold products together, while screws are flexible bolts that can be utilized with or without a nut, relying on the application. Nuts, on the other hand, are internally threaded bolts that companion with screws or screws, offering a protected hold. Washers are important for distributing the load of the bolt and stopping damage to the material being fastened. Furthermore, rivets are long-term fasteners that are optimal for applications where disassembly is not called for. Understanding the differences between these bolt types is vital for selecting the right one for the job, guaranteeing that the connection is solid, long lasting, and trusted. By picking the ideal fastener type, you can optimize the performance and durability of your task - Fasteners and Machining.

Picking the Right Products

Understanding the value of picking the right materials is vital in making certain the optimal performance and reliability of the chosen fastener types discussed previously. When it pertains to bolts and machining applications, the product selection plays a vital duty in determining the overall stamina, toughness, deterioration resistance, and compatibility with the desired environment. Various products supply differing buildings that can significantly affect the efficiency of the bolts.

Common products utilized for fasteners consist of steel, stainless steel, titanium, brass, and light weight aluminum, each having its special strengths and weak points. Steel is renowned for its high strength and resilience, making it ideal for a broad array of applications. Selecting the best product involves taking into consideration factors such as toughness requirements, ecological problems, and budget restraints to ensure the desired efficiency and longevity of the fasteners.

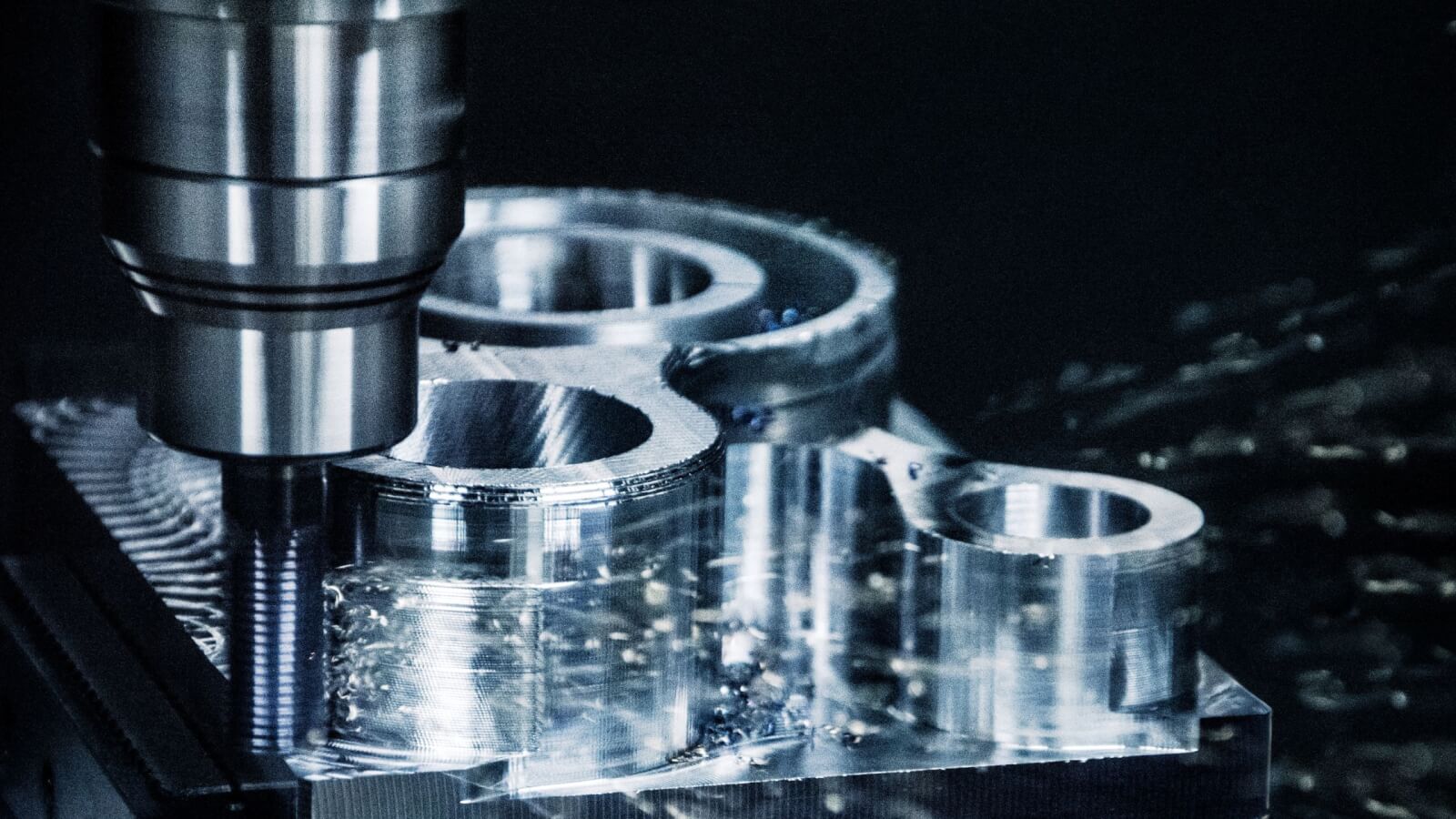

Accuracy Machining Techniques

In enhancement to CNC machining, various other precision techniques like grinding, transforming, milling, and drilling play important duties in fastener manufacturing. Grinding aids achieve great surface finishes and tight dimensional tolerances, while transforming is commonly utilized to produce cylindrical parts with exact sizes. Milling and boring operations are important for forming and developing holes in fasteners, guaranteeing they meet precise requirements and function correctly.

Enhancing Speed and Performance

To maximize fastener manufacturing processes, it is important to simplify operations and apply reliable methods that complement accuracy machining techniques. Automated systems can manage repetitive tasks with accuracy and speed, enabling employees to focus on more complex and value-added activities. By incorporating these techniques, suppliers can achieve an equilibrium in between rate and precision, inevitably improving their competitive side in the fastener market.

Top Quality Control Measures

Applying extensive quality assurance steps is crucial in making sure the reliability and consistency of fastener items in the production procedure. Quality control measures encompass different phases, beginning from the choice of raw products to the last assessment of the ended up fasteners. One fundamental aspect of quality assurance is performing complete product inspections to verify compliance with specifications. This includes examining variables such as product composition, company website sturdiness, and stamina to ensure that the fasteners meet market standards. Additionally, keeping an eye on the machining processes is vital to maintain dimensional accuracy and surface area finish high quality. Utilizing innovative modern technology, such as computerized examination systems and accuracy measuring tools, can enhance the precision and performance of quality assurance treatments.

Routine calibration of tools and machinery is essential to keep consistency in production and make certain that fasteners satisfy the needed tolerances. Applying strict procedures for determining and attending Full Report to non-conformities or problems is essential in preventing substandard products from going into the marketplace. By developing an extensive high quality control structure, manufacturers can support the track record of their brand name and supply bolts that meet the highest requirements of performance and longevity.

Conclusion

In the elaborate realm of bolts and machining, the pursuit for accuracy and rate is a continuous obstacle that requires thorough focus to information and critical preparation. When it comes to bolts and machining applications, the product choice plays an essential function from this source in determining the overall toughness, durability, deterioration resistance, and compatibility with the desired setting. Precision machining involves various innovative approaches that make certain the limited tolerances and specifications needed for bolts.In addition to CNC machining, other precision techniques like grinding, turning, milling, and exploration play crucial functions in bolt manufacturing.To enhance fastener manufacturing processes, it is necessary to simplify procedures and carry out effective strategies that enhance accuracy machining techniques.

Report this page